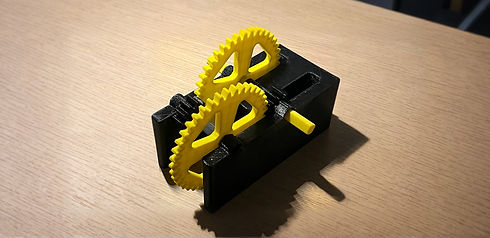

3D Printed 16:1 Reduction Gearbox

The gearbox was an assignment for MIE243: Mechanical Engineering Design Practical. The goal was to design, print, and have a third party assemble the gearbox that has at least a 12:1 reduction ratio, with bonus points added for input/output being colinear.

Design

To aim for bonus marks, we targeted making a 16:1 reduction using two pairs of 4:1 reduction spur gears. The housing is a three-pronged hull with couplings to hold the shafts.

With 3D printing in mind, cutouts in the gears reduced print time and the shafts were beveled to ensure motion transmission from shaft to gear.

Printing

The shaft and gears were designed without tolerance, aiming for a press fit and light sanding if needed. Printing was done through submission to MyFab, the fabrication/rapid prototyping facility at the University of Toronto.

Assembly

To assist third party assembly, inspiration was taken from IKEA-style instructions to ensure clear communication.